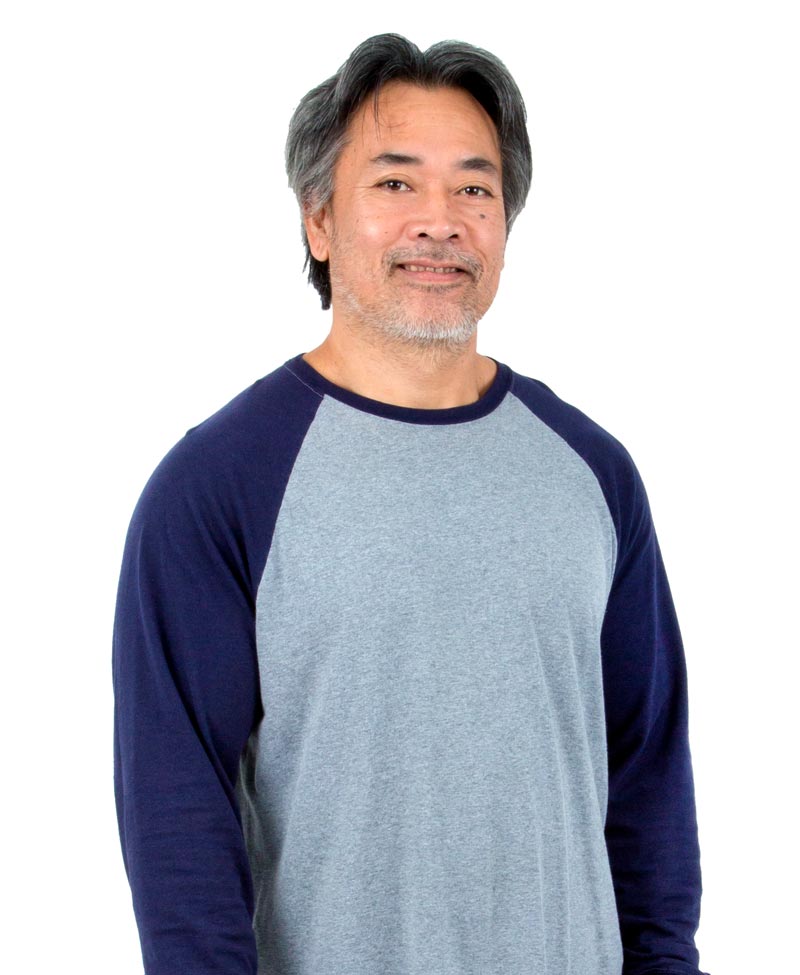

Founded in 1980 and family-owned, GEM Welding includes experts with decades of experience in oxyacetylene welding, brazing, CNC machining, lathe and mill work, and sheet metal fabrication. Despite GEM Welding’s longevity, we remain committed to the principles and values to which the scale of a small business allows us to adhere. Our team of 10 electro-mechanical technicians have a diverse set of experiences in various facets of welding and assembly.

Because of GEM Welding’s vast manufacturing capabilities, clients include medical, industrial, commercial, and military companies. GEM Weldings works with clients who need a finished product, a product repaired, or a prototype assembled. GEM Welders are experienced using a range of metals and products (including casings, joints, sheet metal, and other product types). GEM Welding’s services including prototyping, repair work, general welding and brazing, general machine assembly, and metal fabrication.

What separates GEM Welding from other machine shops includes the speed with which services are consistently delivered. At GEM welding, customers drive our business, which is why GEM Welding strives to maintain a near-perfect record of on-time delivery and non-defective parts.

Our team of experienced professionals knows how to shift priorities to accommodate changing needs of clients and their products. Because GEM Welding are professionals with industry experience themselves, client needs come first.

In addition to speed and efficiency, GEM Welding also prioritizes saving clients money. Our industry experience and proven track record allows us to procure the top materials in a cost-effective manner. Clients can trust GEM Welding to deliver products and perform services with consistent speed and cost-effectiveness.